A Paradigm Shift in Orthodontics

The world of orthodontics is witnessing an exciting transformation. It’s not just about the traditional wire-and-bracket braces anymore. The advent of 3D printed bands for orthodontic appliances is reshaping the way we approach orthodontic treatment. The technological advances we’re seeing today are not just improving the treatment process but also enhancing the patient experience and helping offices save time and money.

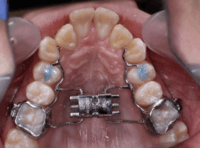

Imagine a practice where workflow is optimized to the maximum. A practice where we can eliminate entire appointments. A practice where patient comfort is enhanced. All these are becoming possible with the use of 3D printed bands. They are stronger, highly reliable, and more effective than the conventional bands .

But where does this strength come from? That’s a fascinating part of the story. The 3D printed bands are made of cobalt-chromium, a material far stronger than the stainless steel of traditional bands. The strength of these bands is not the only advantage. The precise fit that 3D printing allows are also revolutionizing the way orthodontic appliances are utilized.

Enhancing Productivity in the Office

The use of 3D printed bands in orthodontic appliances brings a host of benefits to the office workflow. The most significant is the elimination of the separation appointment. This is the appointment where we traditionally create space for the band by placing separators. With 3D printed bands, this appointment becomes unnecessary. They are digitally designed to fit perfectly without the need for separation.

But that’s not all. Remember the times when we had to worry about mechanical retention? Those days are behind us now. Even though 3D printed bands do not extend sub gingival and their retention is excellent. The band’s retention depends primarily on the bond strength achieved during delivery. This makes the process efficient and reliable, saving valuable time not only in the office but for your patients as well.

Efficiency is not just about saving time, though. It’s also about reducing costs. And this is another area where 3D printed bands shine by eliminating the need for additional appointments and materials, they can significantly reduce overhead costs. This makes your practice more cost-effective and profitable.

3D Printed Bands: Bonding Do’s and Don’t

Step 1

Prophy rinse and dry the Buccal and Lingual surfaces of involved teeth.

Apply Gel Etchant to the full Buccal and Lingual surfaces of involved teeth – DO NOT etch the entire Occlusal. After 30 seconds, suction visible etch from tooth and irrigate thoroughly for 10 seconds per tooth. Desiccate teeth.

Step 2

Apply 1 coat of Assure Plus to entire Buccal surface

and Buccal cusp tips of tooth ONLY.

and Buccal cusp tips of tooth ONLY.

DO NOT apply to Occlusal or Lingual.

Air dry for 3 seconds.

Step 3

Step 3

Apply an even layer of Self Mix Band Lok to tooth side of appliance as the teeth are being primed

with AssurePlus. Band Lok has a 4 minute working time, do not preload appliance until ready to deliver chairside.

Seat appliance to express flash

Step 4

Step 4

Tack cure flash for 1 second ONLY – this will make all the flash cohesive and allow for single piece removal.

Finish Curing from Occlusal opening for 30 seconds per involved tooth. Remove isolation and instruct patient to wait for 5 minutes before activating appliance. Band Lok is a Dual Cure and will always achieve full polymerization.

Finish Curing from Occlusal opening for 30 seconds per involved tooth. Remove isolation and instruct patient to wait for 5 minutes before activating appliance. Band Lok is a Dual Cure and will always achieve full polymerization.

Removal

With a traditional band removal pliers, break appliance from tooth on Buccal side to create cement separation – Band Lok bonds chemically to metal – the majority if not all cement will remove with the appliance.

not all cement will remove with the appliance.

https://shop.fivestarortho.com/collections/bonding-materials

Comfort and Strength: A Winning Combination

Patient comfort is paramount in orthodontics. And this is where 3D printed bands truly excel. No more impressions, no more forcing spacers between teeth. Unlike traditional bands, they cause no blanching of the tissue. This means less discomfort and a more pleasant experience for the patient.

The real icing on the cake, however, is the strength of 3D printed bands. As I mentioned earlier, they are made of cobalt-chromium, which is stronger than stainless steel. This means they are more durable and resilient. This reduces the chance of breakage and the need for replacement, making the treatment more efficient.

3D printed bands for orthodontic appliances are a major leap forward and here at Five Star Orthodontic Laboratory and Supply. They improve efficiency, reduce costs, enhance patient comfort, and are stronger and more durable. It’s a win-win situation for both the orthodontist and the patient. As we embrace this new technology, we are not just transforming our practices. We are redefining the very experience of orthodontic treatment.